AI and robotics are two tech industry buzzwords as common as computers. Every company and product has seemed to innovate their offerings with AI in some fashion, so why shouldn’t solar follow suit?

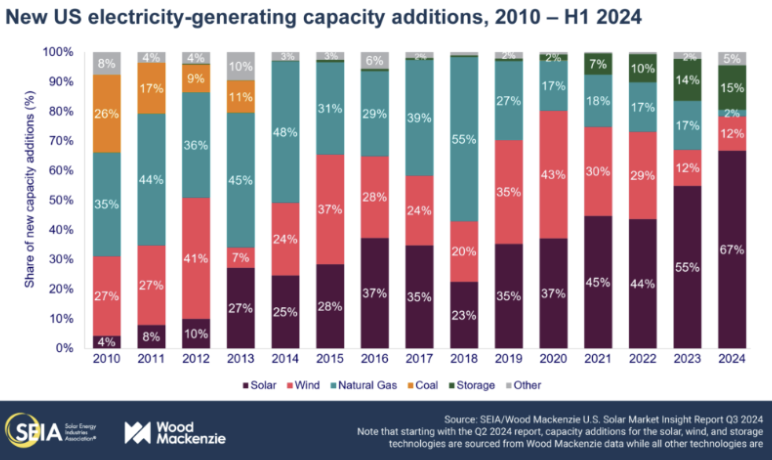

Solar energy installations have grown tremendously over the last decade with no signs of slowing down. According to the Solar Energy Industries Association (SEIA), photovoltaic solar accounted for 67% of all new electric generating capacity in the US – up from only 25% ten years ago in 2014.

Commercial and Utility-scale solar installations are driving the vast majority of that growth. The above report notes that as of Q3 2024, this is how each segment stands:

- Residential Solar: 1,132 MW DC installed in Q2 2024, down 37% from Q2 2023

- Commercial Solar: 427 MW DC installed in Q2 2024, up 6% from Q2 2023

- Community Solar: 270 MW DC installed in Q2 2024, down 12% from Q2 2023

- Utility Solar: 5 GW DC installed in Q2 2024, up 59% from Q2 2023

Table of Contents

Why The Down Trends?

Large-scale solar deployment is seeing major gains because utilities continue investing in the lowest cost and safest forms of electricity, solar and wind. SEIA also notes that pricing for commercial systems is down 12% year over year and utility-scale system pricing is down 2% for fixed tilt and 1% for single-axis tracking.

Unsurprisingly, the continued growth of commercial and utility-scale PV is leading to more investment and innovation in the segment, some of which have the potential to blow the doors off the projections for deployment.

Robotics in Solar

The use of robotics in solar energy is rapidly transforming the industry and providing solutions that increase efficiency, reduce costs, and enhance safety. Robotics have been used for some time in solar module manufacturing to speed up manufacturing processes and remove human error, similar to how to the automotive industry has adopted robotics and automation.

With the explosion in commercial and industrial-scale solar, robotics and automation have begun making their way into the field. Traditionally, installing and maintaining solar farms requires significant labor, with tasks such as panel positioning, cleaning, and inspection being performed manually. However, robotics has started to streamline these processes by automating time-consuming activities.

Construction

One of the most significant limiting factors of solar installation is having manpower at the site. Large-scale solar developments require crews to work long hours lifting heavy modules for weeks to months to survey and prep the site, let alone the additional time it takes to build the systems on-site.

With the rapid growth of the industry, companies have the mindset that “something has got to give” when it comes to resource allocation and optimizing time on site. The five companies below are taking solar installations to the next level with innovative technologies to speed up the installation process.

Maximo by AES

AES Corporation, a global energy company headquartered in Arlington, VA, is the team behind Maximo and introduced it in July of 2024. They designed this robotic assistant to accelerate renewable energy deployment by cutting down on both time and cost.

According to AES, Maximo can install panels twice as fast as humans and at half the cost. Using a technology-agnostic approach, Maximo’s database can work with a variety of clamps, rails, and trackers. Maximo is deployed to a worksite and uses its robotic arm to lift, place, and secure panels to rails.

Sensors, cameras, and LIDAR in combination with AI allow Maximo to create a virtual rendering of the site so that one robotic arm can perfectly place the panel while the other torques the clamps in place.

AES has already deployed Maximo and used the technology to install nearly 10 MW of large-scale solar PV, including projects in California, Virginia, Ohio, and Louisiana.

Sunrise by Charge Robotics

In a similar idea to Maximo, Charge Robotic’s Sunrise fully autonomous solar construction system looks to eliminate the most costly and labor-intensive part of a solar installation. Charge Robotics released this YouTube video, to explain how their solution takes it one step further.

Sunrise is a trailer-mounted autonomous system that can be deployed to a field site. Rather than simply placing modules on existing rails, sunrise assembles panels and rails in sections. From the video, Sunrise uses robotic arms to automatically place and torque panels onto a rail and produce sections for the ground crew.

The ground crews can take the already assembled sections and place them out in the field, significantly reducing the time needed to assemble by hand. By producing fully assembled rail and panel combo pieces, full solar fields could be put together by only a small crew in an almost assembly-line fashion.

Built Robotics Automated Pile Driver

At the base of every large-scale solar field are the steel piles that the railing and panels sit upon. Steel beams can be easily overlooked, but are the foundation of every project and a big source of time lost in the early construction stages.

Built Robotics has developed an automated pile-driving system to ensure maximum accuracy and allow quicker pile placement with fewer errors. With traditional pile driving teams will manually lay out piles, ensure they are on the correct line, and then utilize a machine operated by a crew member to pound in the piles. One crew member operates the machine while others ensure the pile is straight and lay out the next piles. If the pile isn’t driven into the ground correctly it must be redone, wasting valuable time.

Built Robotics RPD 35 and its sidekick, RPS 25, altogether remove site labor from the equation. Built on excavator platforms, the RPD 35 can hold more than 200 piles on the storage racks. The RPD 35 picks up the current pile from its storage, places it on the ground, and drives it in. The RPS holds the pile in place to ensure accuracy and reduce rework. The two operate completely autonomously.

These two robots can work around the clock in any weather condition and Built Robotics claims they work up to five times faster than the most advanced pile drivers on the market. Their website has some great photos of the drivers and their automatic trench diggers, and they also produced a YouTube video of the robots in action.

Surveying

Another labor-intensive part of the solar development process is surveying land. Traditionally done by crews, surveys are done to scope out the work site and determine where piles or ground screws can be placed for the foundations of the solar array. Traditional crews will mark out the areas as accurately as possible so they can come back through and place their foundations in straight lines.

TerraSmart, a solar developer, employs their APSR robot out to sites to automate that process. The APSR is a NASA rover-inspired robot that is programmed to survey sites and can even drill pilot holes for ground screws with remarkable precision.

According to TerraSmart’s website, traditional survey crews were able to locate up to 200 points per day, but using APSR they can locate over 1,300 points per day, drastically increasing the construction speed.

Maintenance

Solar project work doesn’t end once the panels are installed and online, solar farms also need to be maintained so they operate properly and efficiently. To harness premium sunlight, many solar farms are built out in open, arid spaces. Those conditions mean panels are subject to tons of soiling, or dirt covering the panels and reducing the production.

Ecoppia has created solutions for cleaning solar panels at scale in the harshest environments. Their product suite, including the T4, H4, and E4-E4+, are completely autonomous and energy-independent devices that clean off panels.

Ecoppia’s solutions can clean single-axis and fixed-tilt installations by employing car wash-like equipment to safely remove dirt and debris from panels. These solutions don’t use any water and run off their own solar panels, making maintenance a breeze.

Conclusion

These robotic advancements, coupled with AI and computer vision are pushing the boundaries of solar development, simplifying solar installation and operations alike.

On top of the mechanical and personal benefits, utilizing technology like the above gives unprecedented analytical looks at a construction site. Unlike traditional construction crews, an installation site with robotics and AI would be able to give management more predictable installation timelines. and allow them to deploy resources more efficiently.

With continued development and demand, we may soon see a world where commercial and industrial-scale solar is deployed with minimal human interaction and at fractions of the cost seen today.