With millions of individual installations and hundreds of millions of panels currently in use, the US solar industry is on the clock to perfect recycled solar. According to the Department of Energy, about 70% of the solar systems in the US have been installed since 2017. With an average operating lifetime of 30-35 years, that means by 2050 there will be a huge amount of modules coming off of roofs and needing to be dealt with before they end up in a landfill.

As the issue of decommissioned panels looms, the question arises: Can solar panels be recycled? The short answer is yes. But let’s examine how recycling works today and explore opportunities to improve efficiency in the process.

Table of Contents

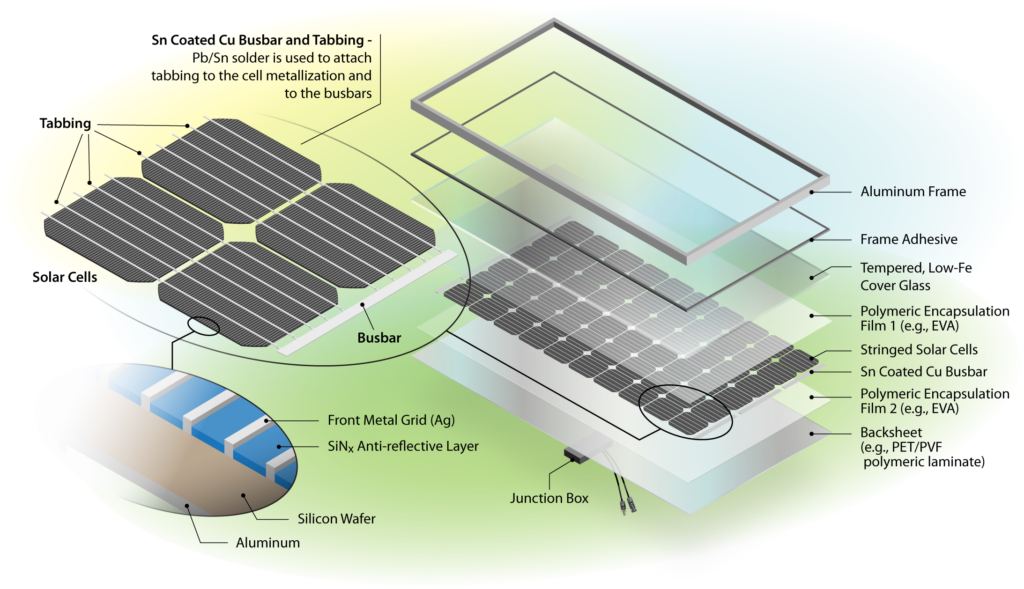

Anatomy of a Solar Panel

To understand how panels are recycled, it’s first helpful to know the components that make up a traditional panel. For this article, we will be focusing on traditional crystalline-silicon solar modules as they make up the majority of the panels used today.

Panels are made up of several layers and only one is the actual electricity producer. The layers include:

- Frame – typically aluminum

- Tempered Low-Fe Glass – The front of the panel will take the brunt of the weather. Low-Fe glass (or low iron) is glass made with much less iron oxide than standard glass. Low-Fe glass has a higher level of transparency.

- Encapsulation Film – Solar panels will have two layers of encapsulation film, a type of plastic designed to seal the solar cells. The layers are inserted on either side of the array of solar cells and then heated to bond the unit together.

- Solar Cells – The main character of the panel. Panels are made of cells – typically 60-72 – soldered together and connected to busbars, which transmit electricity. The solder is typically a lead and tin mixture (Pb/Sn).

- Backsheet – Typically white or black, the back sheet acts as a protective coating for the rear of the panel and adds to the overall aesthetic since it can be seen between the cells.

On the back side of every panel is a plastic junction box where the busbars end. Copper wiring comes out of it, and panels are connected via these wires.

Recycling Process

In terms of what can and can’t be recycled in a panel, thankfully, most of the panel is made up of easily recycled materials. In silicon-based PV panels, glass makes up about 75% of the total weight, and glass recycling is already an established industry. Aluminum makes up almost 10 % of the panel’s weight as well.

The first step of panel recycling is disassembling the panel by removing the frame, glass, and junction box. These can be melted down and reused repeatedly with minimal losses. GreenMatch estimates that 95% of the glass and 100% of the frame can be reused.

The remainder of the panel is a bit more tricky to remove. The plastic encapsulation film is removed and the components are separated. This is achieved by heating the components to temperatures near 500℃ (932℉). The plastic film will evaporate and burn off at these temperatures, leaving the silicon materials for processing.

The exposed solar cells can be etched away using mechanical methods (breaking into small pieces) or melted away with an acid. From there, the pieces can be melted and remade into new silicon wafers for cells.

Solar panels contain some toxic materials, such as lead, which is used in the solder. While this is a relatively small amount, special care needs to be taken to ensure toxic chemicals don’t make their way into a landfill.

A Huge Market Opportunity

According to the International Renewable Energy Agency, The value of recoverable raw materials from old panels will be approximately $450 million by 2030. With the vast majority of panels in the US hitting end of life by 2050, that market and the opportunity it presents is only going to grow.

According to the Department of Energy, there are only seven recycling operations in the US currently and the largest capacity tops out at 500 MWdc/year.

Where Can The Process Be Improved?

Obviously, the biggest innovations will come as this market evolves here in the US. As is true with many products in the US, it’s currently cheaper to simply throw away panels rather than to go through the recycling process.

The biggest improvement panel recycling can achieve would be to determine what happens to the recycled silicon material. If this material were made into a 100% recycled panel, what would be the production and efficiency losses? Would there even be any? Having a panel manufacturer open up that uses 100% recycled panels could be huge for the market, assuming there’s not a massive loss in power. Even if there is a big power loss, if the cost of those panels was significantly less, it would appeal to the majority of consumers.

The other area where recycling needs improvement is toxic materials. Metals like lead and cadmium are present in some panels, so research needs to be done on either removing these materials on the front end or rendering them inert before they end up in a landfill.

Overall, the recycling industry is still evolving, but it is poised to become a dominant force in the near future. As technology advances and sustainability becomes an increasingly critical priority, the potential for solar panel recycling to play a central role in the green economy is undeniable. The future of solar energy depends on our ability to innovate and optimize recycling processes.